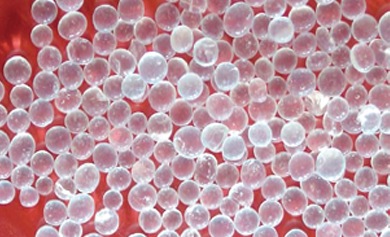

Varous rubber materials can be produced from high technical skills

Daeyoung High-Chem has independent key technology made of various rubber material processed.

A rubber material, containing the original property, can be used by itself. But it is produced by adding a lot of chemicals mixed according to the kinds of rubber, the purpose of use, environment usage which is demanded for improving mechanical property, and the extension of durability.

Rubber material is produced by adding organic and inorganic chemicals mixed together, The mixing process is the key technology process to improve of product quality.

- NBR Nitrile Butadiene Rubber

- NBR contains more ACN, from 18% to 50% which generally makes it different

- Generally it has an excellent mechanical property

- It uses temperature ranging from -30‚ĄÉ~100ÔĻé but uses until 120‚ĄÉ for short term Suitable NBR that are produced use until -60

- FKM is mainly used high temperature with oil containing mineral or grease component

- FKM Fluorocarbon Rubber

- FKM contains more fluorine and structure, chemical resistant and low temperature property of rubber makes it different

- It is well known as non-flammability, low gas permeability, ageing resistance, ozone resistance and excellent climate resistance

- It uses temperature ranging from -20‚ĄÉ~200‚ĄÉ but uses until 230‚ĄÉ for short term. -Suitable FKM that are produced use until -35‚ĄÉ

- FKM is mainly used high temperature with oil containing mineral or grease component

- EPDM Ethylene Propylene Diene Rubber

- EPDM contains good heat-resisting property, ageing resistance and ozone resistance

- It has an excellent tensile strength, insulating property and low temperature property

- It uses temperature ranging from -45‚ĄÉ~150‚ĄÉ but uses until 175‚ĄÉ for short term Vulcanized EPDM that is shrunk temperature ranging from -45‚ĄÉ~120‚ĄÉ but uses until 150‚ĄÉ for short term

- EPDM is mainly used with brake oil containing glycol and high temperature water

- HNBR Hhdrogenated Nitrile Butadine Rubber

- HNBR is made of NBR which is selected from selective HYDRATING.

- HNBR property contains more ACN and saturation, from 18% to 50% which generally makes it different.

- It has an excellent mechanical property like NBR.

- It uses temperature ranging from -30‚ĄÉ~140‚ĄÉ with oil containing mineral or grease component but uses until 160‚ĄÉ for short term. Special type can be used until -40‚ĄÉ

- Q Silicone Rubber

- Silicone rubber is well known as heat-resisting property, low gas permeability, excellent substance component and it has excellent resistance to special oxygen and ozone

- It uses temperature ranging from -60‚ĄÉ~200‚ĄÉ depend on materials but uses 230‚ĄÉ for short time. Special type can be used until -90‚ĄÉ and some of them are affected by small range of temperature

- Silicone generally uses Drug industry and Food industry

- CR Chlorprene Rubber

- CR is excellent to ozone resistance, chemical resistance, weatherproof and ageing resistance

- It has an excellent mechanical property, non-flammability and low temperature property

- It uses temperature ranging from -40‚ĄÉ~100‚ĄÉ but uses 120‚ĄÉ for short term, special type can be used until -55‚ĄÉ

- CR material uses sealing material and uses like refrigerator and manufacture of adhesives.

- ACM Polyacrylate Rubber

- ACM's power is in the middle class and low tensile strength, limited low temperature property but it has excellent resistance to ozone resistance, weatherproof, hydrothermal resistance

- It uses temperature ranging from -20‚ĄÉ~150‚ĄÉ but uses 175‚ĄÉ for short, special type can be used until -35‚ĄÉ

- ACM material usually uses parts of an automobile in need of a special resistance forlubricant containing addictive substances (containing sulfur) in high temperature.

- FFKM Perfluoro Rubber

- FFKM rubber has wide chemical resistance and strong heat-resisting property like PTFE

- It is weak to expansibility of all media

- It uses temperature ranging from -25‚ĄÉ~240‚ĄÉ but special type can be used until 325‚ĄÉ.

- FFKM uses high temperature or aggressive circumstance and it generally uses in chemical industry